Roadmap to Zero Discharge of Hazardous Chemicals (ZDHC)

The garment and footwear industry are one of the biggest contributors to modern fashion. The production of garments and footwear is a complicated process which involves the use of a lot of chemicals. A very small amount of these chemicals used in production is absorbed by the fabric/garment and leather footwear. As a result, a large amount of the chemicals ends up as waste discharged into water. However, many chemicals used in the textile and leather industries are harmful to the environment and all living things.

There are various country specific regulations in every part of globe, but none of regulations deals with chemicals used specifically in the textile and leather footwear industry.

To overcome this, ZDHC was started in 2011, as a response to the Greenpeace Detox campaign. Initial work established a joint roadmap that demonstrated the collaborative efforts and steps needed to lead the apparel and footwear industry towards zero discharge of hazardous chemicals for all products across all pathways by 2020.

Membership has grown from six brands in 2011 to approximately thirty-five today. The group is diverse and includes:

- Brands from Europe and the USA.

- Sportswear, Luxury and Fashion brands

- Multi-billion-dollar companies as well as small niche brands

ZDHC Principles

Apparel and footwear supply chains are long, complicated, and continuously moving into developing countries where labor is cheap. Due to poor and less knowledge and awareness, manufacturing facilities and workers in these countries need training to implement a chemicals management program. ZDHC has established and implemented the following competencies to drive their work.

- Capture and share best practices

- Use management systems thinking

- Open transparent communication

- Engage with stakeholders across different regions and cultures

Joint Roadmap

The Joint Roadmap was published at the end of 2013. Projects were divided into seven workstreams to provide a much more focused approach.

In 2014 and 2015 ZDHC made significant strides towards their goal of zero discharge of hazardous chemicals, including the establishment of a standalone ZDHC legal entity based in Amsterdam, strengthening the organization and ZDHC Program.

New processes and program documents were developed and published. These documents signify a standardized approach to tools and processes, resulting in a reduction in workload, simplicity, improved communication, and cost savings.

These Documents include:

- Framework for the Prioritization of Hazardous Chemicals.

- Chemical Guidance Sheets provide information about the 11 classes of hazardous chemicals identified by Greenpeace.

- A Manufacturing Restricted Substance (MRSL).

- A Research List. This contains chemical substances where an alternative may not exist. The list sends a message that ZDHC will phase these chemicals out once an acceptable alternative has been identified.

Updated Joint Roadmap

- The ZDHC Program provided a Joint Roadmap update in late 2015. The update transitions seven workstreams into four focus areas to support the entire supply chain in adopting improved chemical management practices.

- Wastewater quality: Benchmarked existing standards and existing data at facilities, developed a guidance document and promoted the inclusion of functioning wastewater treatment plants at manufacturing facilities.

- Updated MRSL now includes leather-processing chemicals. In addition, they will align on a conformance process, engage stakeholders, and scale the tool.

- Defined process for finding safer alternatives, developed process to add and remove substances from the research list and engaged stakeholders to find alternatives to chemicals of concern.

- Aligned the audit protocol with the Higg index and other similar organizations to develop and finalize an assessment process and engage groups to promote the adoption and use of the audit protocol.

ZDHC also established the below work that cuts across all focus areas:

- Data and disclosure

- Training

As a continues improvement process, on March 2022, ZDHC published wastewater guideline version 2.0 and on November 2022, ZDHC version 2.1 which includes:

- ZDHC MRSL Wastewater Parameters and Reporting Limits, Table 1A-1T.

- ZDHC Heavy Metals Wastewater Parameters and Limits, Table 2.

- ZDHC Conventional Parameters and Anions for Wastewater, Table 3.

- ZDHC Sludge Disposal Pathways, Parameters and Limits, Table 4A-4C.

- ZDHC Wastewater Candidate List, Table 5.

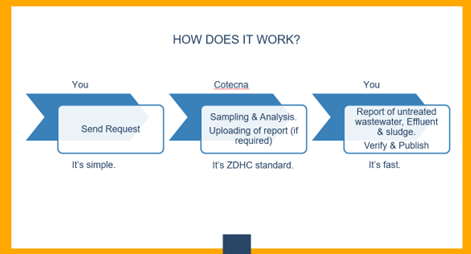

As ZDHC approved solution provider and wastewater testing laboratory, Cotecna Inspection India Pvt. Ltd. (CPS) serves textile and leather footwear industries in sampling, testing, and uploading the reports on ZDHC gateway which helps improve visibility of suppliers to various stakeholders/global brands.

Latest News

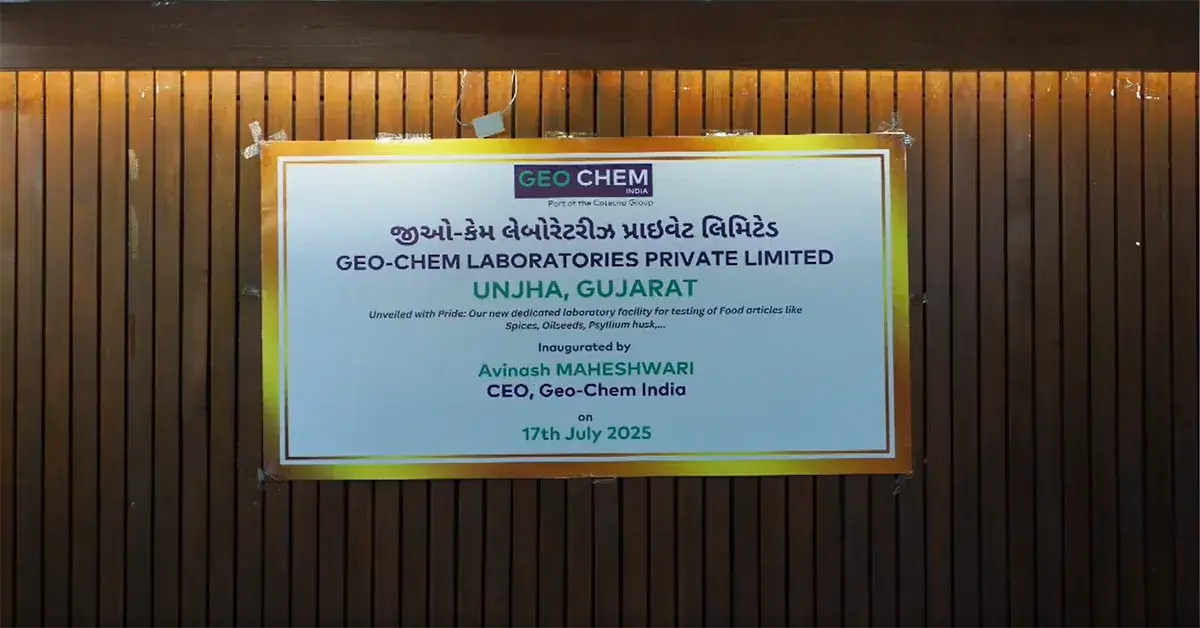

24.07.2025

Geo-Chem Launches New Food Testing Lab in Unjha, Gujarat, India

Geo-Chem India expanded its scope of work in Gujarat with the launch of a new food testing laboratory.

08.04.2025

Innovation and Precision: How Complex Diagnostics Are Transforming Plant Health in the Field

Harnessing Technology for Smarter, More Sustainable Crop Protection.