Enhancing Excellence in Pharma: The Importance of cGMP Training

In the fast-evolving pharmaceutical industry, staying compliant with current Good Manufacturing Practices (cGMP) is non-negotiable. It's not just about meeting regulatory requirements; it's about ensuring the safety, quality, and efficacy of the products that patients rely on every day.

There are three key reasons why cGMP training is crucial for our industry. These include:

1) Compliance with Regulations: Adhering to cGMP standards helps us meet stringent regulatory requirements set by agencies like the FDA and EMA, avoiding costly penalties and ensuring market access.

2) Ensuring Quality and Safety: Proper training ensures that our manufacturing processes are consistent and controlled, minimizing the risk of contamination and errors, and safeguarding patient health.

3) Boosting Market Credibility: Commitment to cGMP builds trust with healthcare providers, patients, and regulatory bodies, enhancing our reputation and competitiveness in the global market.

Key Training Components

- Regulatory Overview: Understanding the framework and guidelines from major regulatory bodies.

- Documentation: Mastering SOPs, batch records, and change control processes.

- Facility and Equipment: Maintaining and validating equipment to meet high standards.

- Process Controls: Implementing rigorous validation and in-process controls.

- Quality Assurance: Establishing robust quality systems and laboratory controls.

- Personnel Hygiene: Emphasizing personal hygiene and safety practices.

- Risk Management: Utilizing risk assessment tools to mitigate potential issues.

To learn more about the Cotecna Group's Pharmaceutical laboratories and our full scope of services, please visit our dedicated Pharma service page.

Latest News

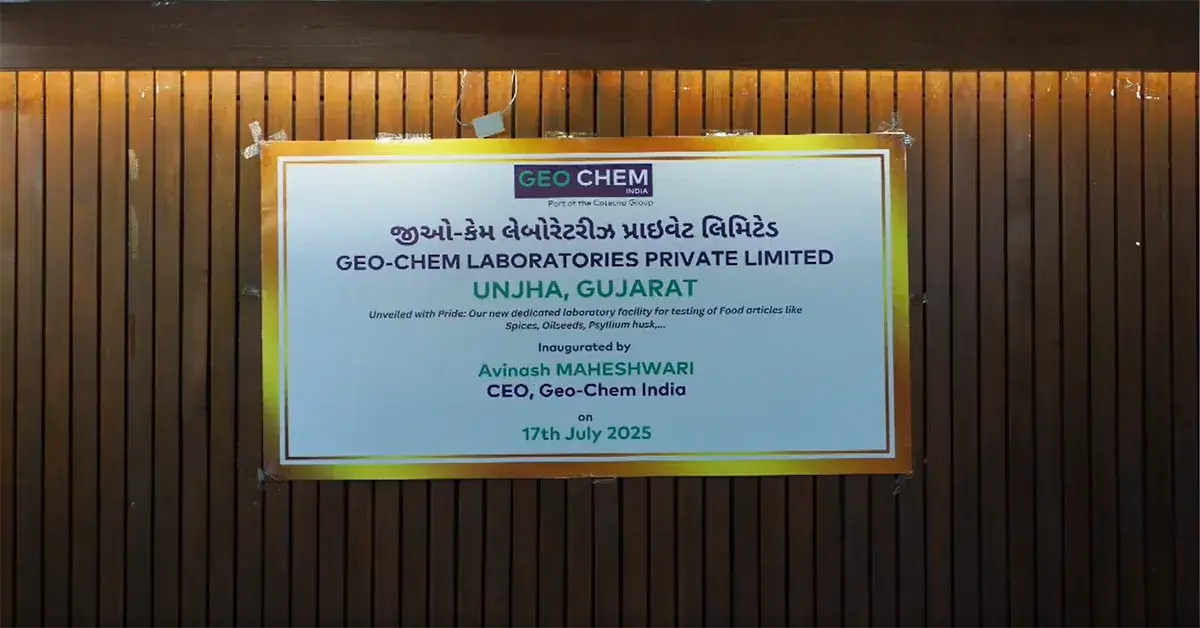

24.07.2025

Geo-Chem Launches New Food Testing Lab in Unjha, Gujarat, India

Geo-Chem India expanded its scope of work in Gujarat with the launch of a new food testing laboratory.

08.04.2025

Innovation and Precision: How Complex Diagnostics Are Transforming Plant Health in the Field

Harnessing Technology for Smarter, More Sustainable Crop Protection.